In the realm of nanomaterials, graphene oxide stands out. This remarkable substance intrigues researchers, engineers, and innovators globally, opening doors to new possibilities. Let's delve into their wonders and their potential across industries.

Graphene oxide (GO) is derived from graphite oxidation, commonly using the Hummer method. This involves treating graphite with potent oxidizing agents like potassium permanganate and sulfuric acid, followed by exfoliation to produce GO sheets. Prof Ali’s research group at TIET is working on the synthesis, modification, and catalytic applications of GO and reduced GO (rGO).

CEEMS, a collaborative effort between Virginia Tech, USA, and Thapar Institute of Engineering and Technology, Patiala, spearheads research and innovation. They tackle pressing global challenges by harnessing big data, nanotechnology, and molecular biology to combat climate change and inequality, catering to global needs. Their focus on coal-derived graphene promises breakthroughs in medicine, energy, and the environment. Through global partnerships and interdisciplinary approaches, CEEMS fosters a fairer, sustainable future.

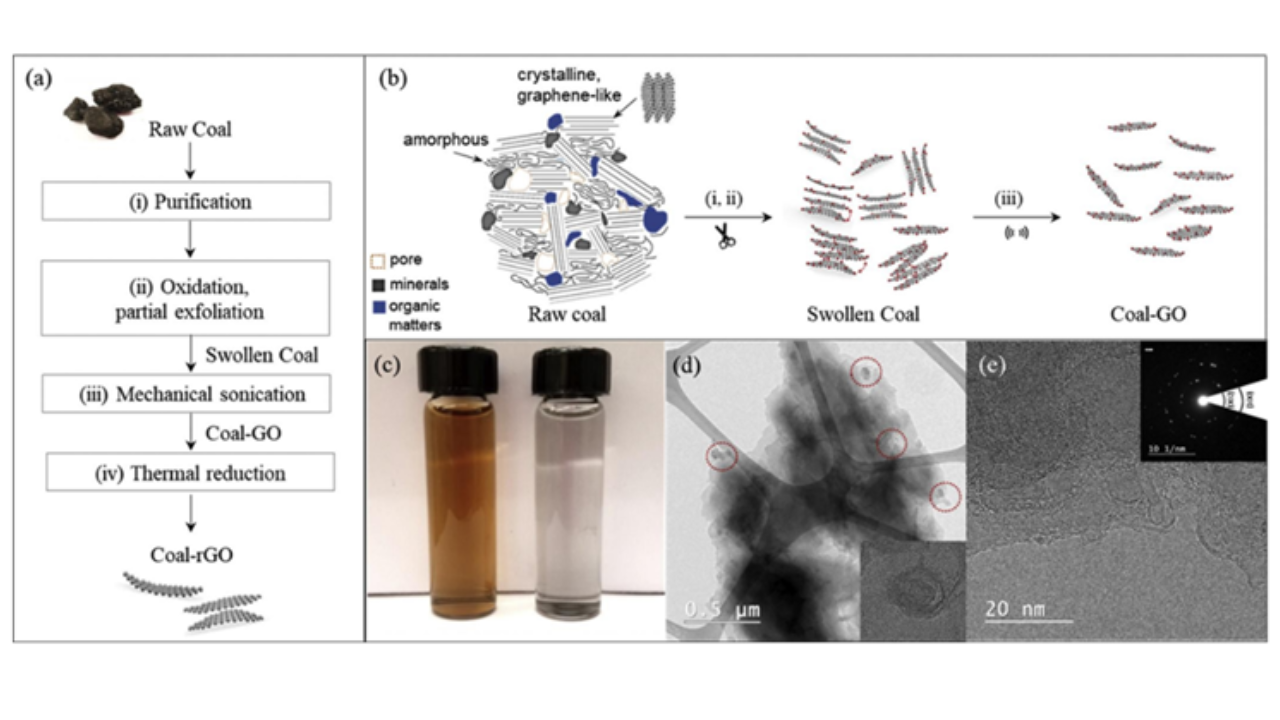

The TIET CEEMS lab adopts an innovative one-pot technique for GO production, developed by Professor Mahajan and colleagues, including Dr. Roop L. Mahajan from VT and Dr. Rajeev Mehta from TIET. This method synthesizes graphene-x from coal, offering economic and environmental advantages over conventional methods. Adaptation of this process to Indian coals ensures optimal utilization of graphene's unique properties.

CEEMS aims to lead in graphene research, facilitating large-scale production for practical applications. By scaling up GO synthesis and exploring graphene derivatives, CEEMS aims to revolutionize science and engineering.

Graphene Oxide: A Snapshot

Derived from graphene, the two-dimensional honeycomb lattice of carbon atoms, graphene oxide emerges as a remarkable derivative. Through oxidation, graphene transforms, introducing oxygen-containing functional groups like hydroxyl and epoxide. These alterations give birth to a material with properties as diverse as its applications.

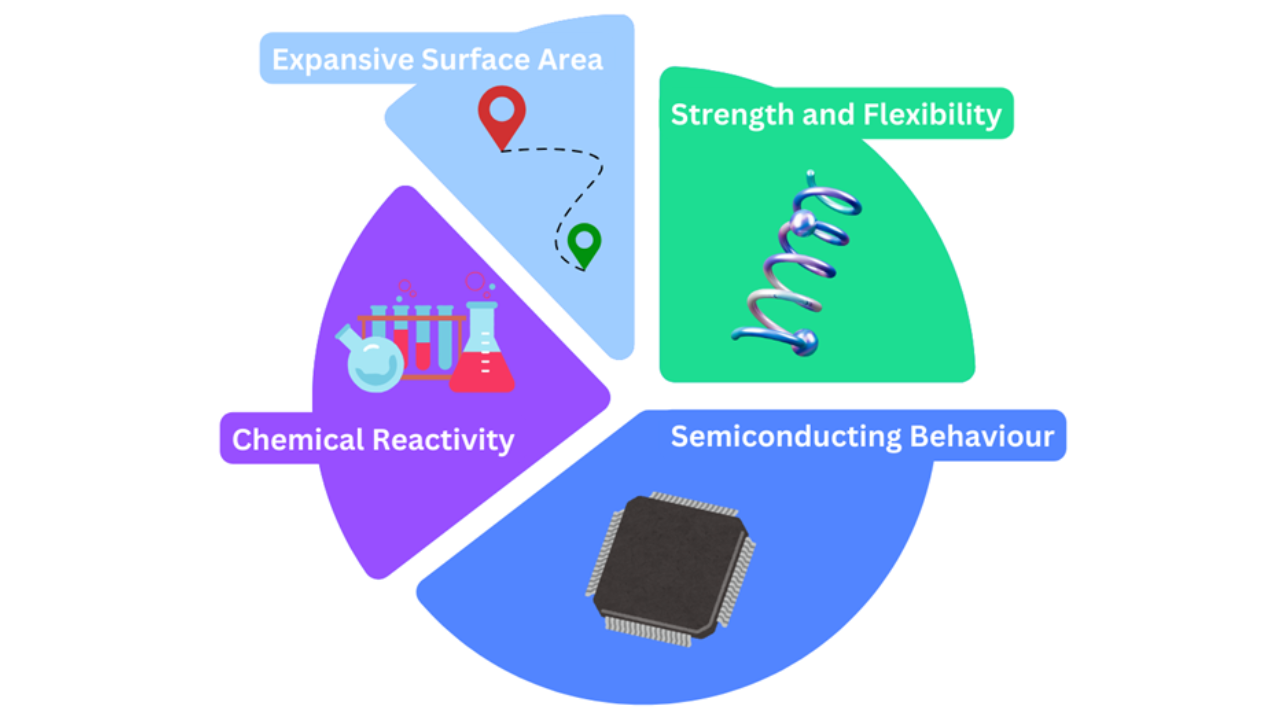

Strength and Flexibility: Though slightly tamed compared to its parent, graphene oxide retains remarkable strength and lightweight properties, ideal for applications demanding durability.

Semiconducting Behaviour: With their oxygen groups introducing band gaps, graphene oxide becomes a versatile player in electronics and optoelectronics, offering controlled conductivity.

Chemical Reactivity: The reactive nature of their oxygen groups opens doors to myriad applications in sensors, catalysis, and biomedical fields.

Expansive Surface Area: Featuring a generous surface area, graphene oxide becomes a powerhouse in adsorption processes, energy storage, and drug delivery systems.

Properties of Graphene Oxide

A streamlined method for producing graphene oxide (GO) from coal using a single vessel process:

i. Commence with coal, an easily accessible and plentiful substance.

ii. Subject the coal to nitric acid (HNO3), which exhibits a vigorous reaction with the carbon surfaces of coal.

iii. HNO3 chemically adds oxygen-containing groups to the carbon surfaces, including those with poly-aromatic structures like graphene.

iv. This technique conserves and isolates graphitic domains within the coal while eliminating other aliphatic carbon chains by oxidation.

v. Conduct trials using varying quantities of HNO3, oxidation durations, and temperatures in order to enhance the efficiency of the procedure.

vi. The final product obtained is graphene oxide (GO) that is created from coal, and it may be further reduced to obtain reduced graphene oxide (rGO).

This single-step procedure provides a straightforward approach that is economical and requires less chemical consumption as compared to conventional techniques such as Hummers' method. It requires a less number of stages and produces a reduced amount of waste, making it a potential method for producing graphene oxide on a big scale. Furthermore, the graphene oxide derived from coal maintains its crystalline structure, suggesting their potential for many uses.

Legend

(a) Flow chart, (b) schematic illustration of one-pot process for the GO production from coal ((i): purification, (ii) oxidation and partial exfoliation, (iii) mechanical sonication, (c) camera images of the Coal-GO and Coal-rGO aqueous solution, (d)TEM image of the Coal-GO (inset: magnification of nanoscrolls), and (e) TEM image of the Coal-rGO (inset: SAED pattern).

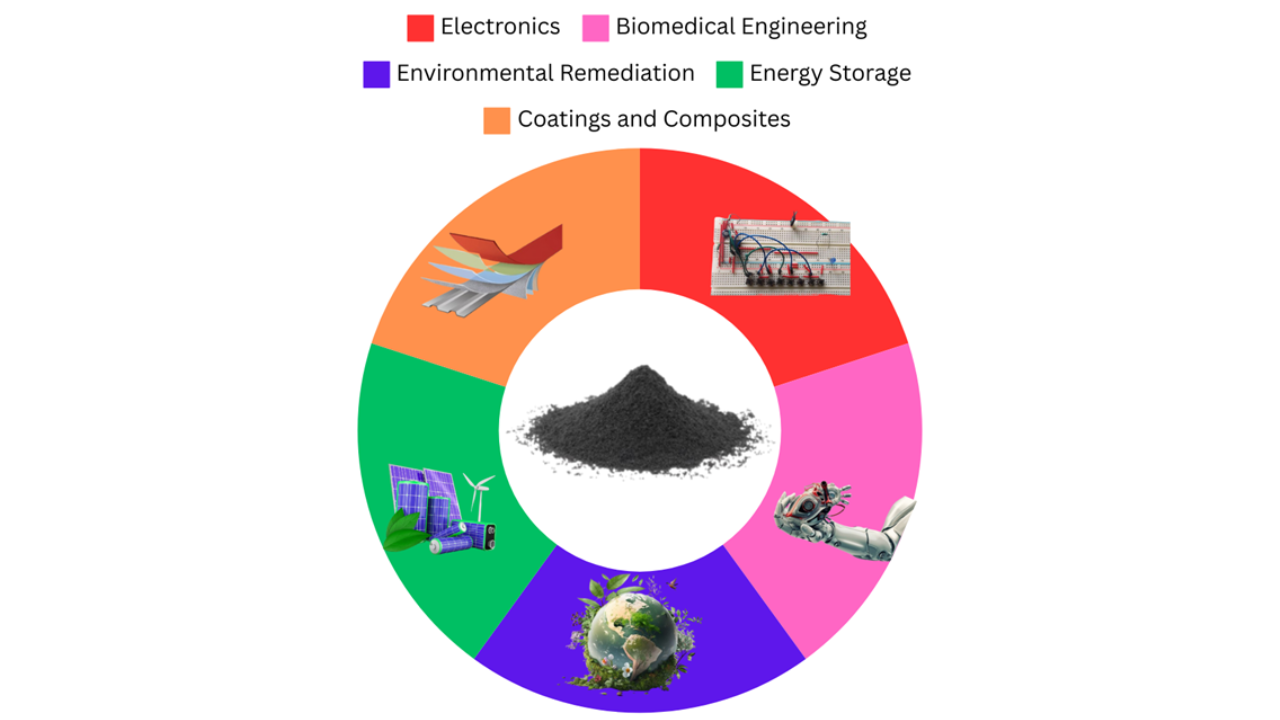

Electronics: Witness their prowess in crafting flexible, transparent conductive films for touchscreens and solar cells. Their semiconducting properties hint at the future of transistors and sensors.

Biomedical Engineering: From drug delivery to tissue engineering, graphene oxide plays a vital role, thanks to their biocompatibility and targeted drug delivery capabilities.

Environmental Remediation: Step into the realm of environmental sustainability, where graphene oxide aids in water purification and pollutant removal, combating environmental hazards.

Energy Storage: Explore the realm of energy storage, where graphene oxide-based materials promise advancements in supercapacitors and batteries, offering enhanced conductivity and strength.

Coatings and Composites: Witness industries like aerospace and automotive embracing graphene oxide for improved mechanical strength, thermal stability, and barrier properties. Application of graphene oxide

Application of graphene oxide

Growing the production capacity of graphene oxide at CEEMS.

Usually, research laboratories primarily produce graphene oxide in small quantities for experimental purposes and feasibility studies. With the progress in synthesis techniques and scaling-up efforts, production capacities may expand to fulfil the requirements of industrial applications.

Navigating Challenges, Embracing the Future

Despite its promise, challenges such as scalability and cost-effectiveness loom large. Yet, ongoing research promises solutions, paving the way for graphene oxide to redefine technology, healthcare, and environmental sustainability. As they push the boundaries of synthesis techniques and functionalization methods, the future holds boundless opportunities for this remarkable material.

Conclusion: A Gateway to Tomorrow

Graphene oxide isn't just a scientific curiosity; they are real-world solution providers, offering a glimpse into the potential of nanotechnology and materials science. As we continue to unravel their capabilities and refine their synthesis, the journey with graphene oxide promises to be nothing short of exhilarating, paving the way for groundbreaking innovations in the 21st century and beyond.

Patent

Patent 45, titled "One-pot process for synthesis of graphene and graphene-derivatives from coal," with Serial No.: 62/780,502, is currently pending approval. This patent was developed by Professor Mahajan and colleagues, including Dr. Roop L. Mahajan from VT and Dr. Rajeev Mehta from TIET.